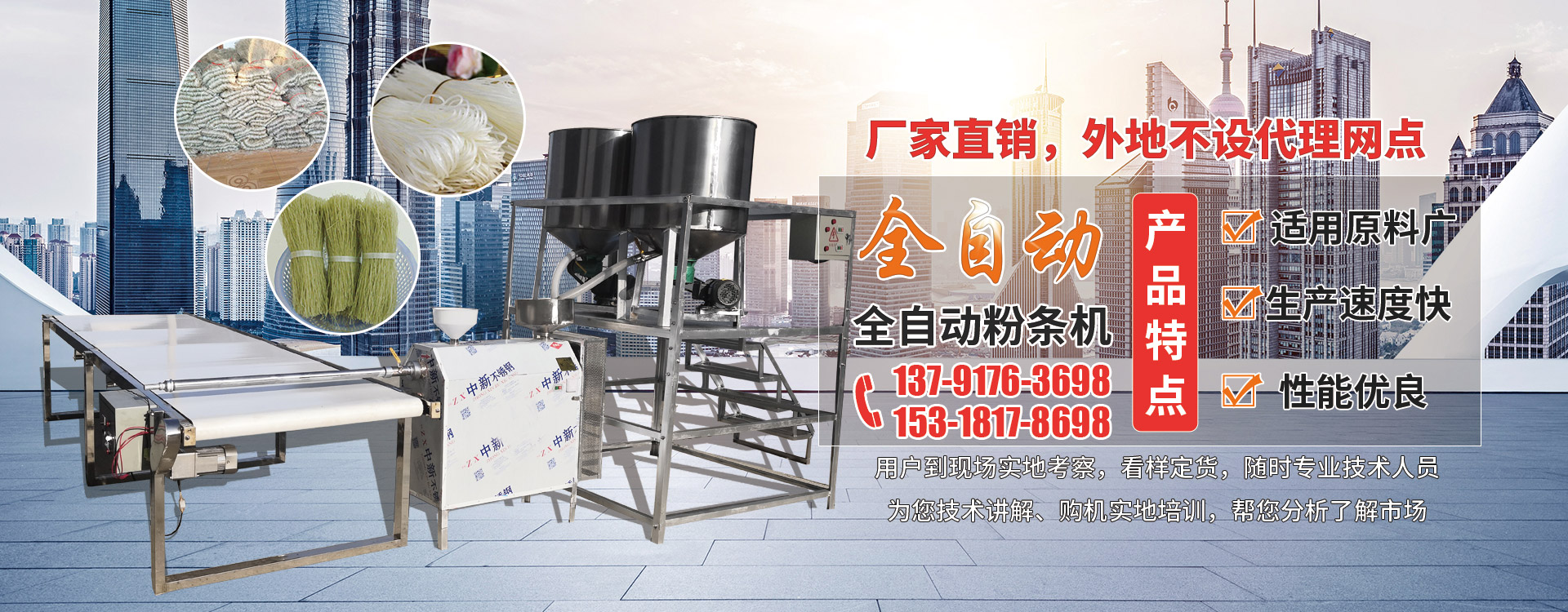

我們在使用雙螺桿擠出機的時候,需要對機器本身有一個清晰的認識,這樣我們才能夠更方便、更有效率的進行產品的生產,在進行雙螺桿擠出機的保養的時候,我們需要定期對機器進行檢查,尤其是對螺栓刀口進行排查,我們必須加強刀片與刀架之間的固定性,保證軸承之間的潤滑,這樣才能夠讓機器更好的進行工作,如果遇到損壞,則需及時進行零件的更換。

當我們使用雙螺桿擠出機的時候,我們需要了解說明書的使用,并且對雙螺桿擠出機的操作要點有一個基本的了解,更重要的是掌握螺桿的結構特性,目前擠出機有單螺栓、雙螺栓、多螺栓等不同的型號,每種型號的操作流程必然是不同的,只有掌握其中訣竅,才能更好使用。 當我們使用一款雙螺桿擠出機的時候,需要對其型號有一個清晰的認識,一款雙螺桿擠出機需要與后續配套的裝置一起使用,才能夠生產出不同結構的塑料產品,只有對其操作特點有個詳細的了解,才可以充分發揮機器的性能,從而讓效率更高。

What should you pay attention to when using a twin-screw extruder?

When we use a twin-screw extruder, we need to have a clear understanding of the machine itself, so that we can produce products more conveniently and efficiently. When maintaining the twin-screw extruder, The machine needs to be inspected regularly, We must strengthen the fixation between the blade and the tool holder and ensure the lubrication between the bearings, so that the machine can work better. If it is damaged , parts need to be replaced in time.

We also need to have a basic understanding of the operating points of the twin-screw extruder.. The operating procedures of each type must be different. A twin-screw extruder needs to be used with subsequent supporting devices to produce plastic products with different structures.